Despite the Hype, Don’t Expect Electric Vehicles To Run Gas-Guzzlers Off the Road

By Emily Washburn

Last week President Biden rolled out yet another government plan to get Americans to ditch their gas-guzzling cars and go electric. He signed an executive order setting a non-binding target for electric, hybrid and hydrogen fuel-cell vehicles to make up 50% of U.S. sales by 2030, up from 2% now.

That goal is fanciful, but electric vehicles, hailed as the answer to climate change, have been swathed in fantasy and fanfare for years. This has masked valid questions about the feasibility and wisdom of government crusades to put one in every garage. Indeed, a range of serious economic, logistical and environmental obstacles suggest that electric vehicles won’t be taking over the roads anytime soon, if ever.

The momentum behind electric vehicles certainly seems unstoppable. General Motors plans to spend $35 billion by 2025 on 30 new electric models and says it will stop selling combustion-engine vehicles by 2035. Mercedes-Benz and Volvo promise to sell only electrics by 2030. California is banning the sale of new gasoline- and diesel-powered vehicles in the state as of 2035. Biden’s infrastructure bill, which the Senate passed on Tuesday and is now with the House, would spend billions to install charging stations around the country and billions more on new transmission lines to boost the electrical grid’s capacity.

It’s unlikely, however, that electric vehicles will supplant standard vehicles until there’s a real market for them, and today the market is largely artificial. State and federal governments goose the supply and demand of electrics by providing tax breaks, direct cash payments and other incentives to both consumers and manufacturers. By tightening emissions regulations and other environmental restrictions, they’re driving up the cost of making, buying and operating gas-powered vehicles, making electrics more competitive.

But industrial policies such as this have a terrible track record—it’s very difficult for governments to will an industry into existence no matter how much money they spend. Even with this extensive intervention in the market, electric vehicles make up less than 1% of the cars, SUVs, vans and pickup trucks on the road, though this year they are picking up market share.

When a government halts its incentive payments, the market topples. Georgia ended its $5,000 tax credit for electric-vehicle buyers in 2015, leading to an 89% drop in sales the following two months. In 2019 and 2020, Tesla sales slowed, partly because they were no longer eligible for the federal tax credit. Electric vehicles have proven so hard to sell that 20% of Cadillac dealers chose to give up their dealerships rather than make expensive upgrades to handle electric cars.

Mark Mills of the Manhattan Institute puts it this way: “If people really wanted electric vehicles, you wouldn’t have to subsidize them. No one had to subsidize the car when the world went from horse and buggies to cars. We have to subsidize now because electric vehicles aren’t an environmental or operational improvement.”

In some ways, it’s good that plug-in vehicles aren’t jamming the roads: The U.S. doesn’t have the infrastructure to support them. The aging electrical grid struggles to meet the current demand for power: In the past decade, power outages have gone up 50%. And there aren’t nearly enough charging stations to support a switch to electric vehicles and make drivers comfortable about venturing far from home. The chargers that are available are not spread evenly across the country. California claims a third of all charging stations; Alaska has 26.

Even if this infrastructure eventually gets built, at an enormous cost, the basic rationale for electric vehicles—that they help reduce climate change—is questionable. Electrics use fossil fuels, too: Power plants produce 60% of their electricity from natural gas, coal and oil. And trading combustion engines for plug-ins is trading oil-and-gas drilling for mining the lithium and other minerals that go into the vehicle’s batteries.

Then, when it’s time to junk the car, it’s difficult to dispose of the batteries because the lithium is highly flammable. “There are no mechanisms for [increasing electric-vehicle usage] without extracting materials from the earth,” says Mills. “The challenge is the perception that there is some magic solution that doesn’t have environmental impacts.”

The most daunting roadblock for a widespread adoption of electrics any time soon may be a practical one. Gas-powered vehicles last a long time—the average age of the ones now on the road is 12 years, and that average has been rising as they become better-built and more reliable. If one of Biden’s goals, an all-electric fleet by 2050, is to be reached, auto companies must stop making combustion engines by 2035 or sooner.

Getting the Power

Much of the U.S. electrical grid was built in the 1950s and ’60s with a 50-year life expectancy, so parts are now operating up to 20 years past their expiration date. At least 640,000 miles of high-voltage transmission lines are working at capacity, noted an American Society of Civil Engineers report in 2017. At the same time, U.S. electricity consumption is growing rapidly and is expected to double by 2050, according to a Princeton University study. So even if the grid were new, it wouldn’t have the bandwidth to handle the demand from a dramatic increase in electric vehicles.

Biden’s infrastructure bill proposes spending $65 billion to put up new transmission lines. That will take years because each line must go through lengthy approval processes, typically slowed by environmentalists worried about damage to the landscape and by nearby residents. But a complete modernization and expansion of the grid would cost at least $4.8 trillion, and until that happens, a major switch to electric cars is a non-starter.

Electrics also must overcome the lack of charging stations. The U.S. has 41,000 public charging stations, compared with 150,000 gas stations. But many are inside parking garages while others serve just specific vehicles or residential developments. With so few electrics on the road, the private sector isn’t ready to start building lots of charging stations, as it did with gas stations in the early years of the last century, so governments are spending tax dollars to build them.

The infrastructure bill would allocate $7.5 billion for new chargers; proponents claim that’s enough to build 500,000 outlets in the next decade. But industry consultants, such as AlixPartners, estimate that the true cost of adding that many chargers is $50 billion to $60 billion. That’s because the price of a direct-current fast charger for public use can be anywhere from $100,000 to $250,000.

Cars for the Wealthy

Electric vehicles come with high price tags. They can cost 10% to 40% more than the equivalent non-electric. The most expensive model sold by Tesla costs $200,000; Audi’s top model is $164,000. The least expensive electrics, made by Nissan and Mini Cooper, can still cost $32,620 and $30,750 respectively. The average price of a new electric is $51,532, according to Kelley Blue Book, compared with $40,326 for a full-size gas-fueled car.

To push more electrics out of dealer showrooms, the federal government offers tax credits of up to $7,500 for purchasing certain vehicles. And the credits can be combined with state incentives for more savings. Nearly all states offer inducements such as tax breaks, rebates and discounts on tolls. But subsidies can encourage sellers to raise the price of a product to capture the subsidy, so it’s not clear how much buyers benefit.

Then-Vice President Joe Biden inspects a Chevrolet Bolt at the 2017 Detroit auto show. Image credit: Geoff Robins/AFP via Getty Images

Then there’s the cost of electricity. To save money by charging at home, a car owner needs to spend up to $1,800 to buy a slow, Level 2 charger and mount it in the garage. Recharging on the road at a public charger can be much more expensive. For example, Chevrolet says its all-electric Bolt gets 25 miles from each hour of charging from a Level 2 station. That would cost between $2.40 and $3.60 at a charger installed by Blink, a Miami Beach company that makes and operates charging stations nationwide. But a gas-powered Chevy Cruz can go 25 miles for only $2.15, according to a U.S. Environmental Protection Agency estimate. (Drivers who don’t have garages and park on the street or in lots may never have easy access to chargers at home.)

Electrics do cost less to maintain than standard cars. Consumer Reports says buying a Tesla Model 3 over a gas-powered BMW 330 or an Audi A4 saves owners $17,000 over the car’s lifetime, with the average savings on the average electric closer to $4,500.

Given all the costs, it’s not surprising that low-income drivers are avoiding plug-ins. Wealthy buyers reaped the most benefit from the federal subsidies while families making under $50,000 earned less than 1% of the tax credits, according to a 2018 study by the Pacific Research Institute.

Not So Green in the End

Combustion-engine vehicles pollute the air, release greenhouse gases into the atmosphere and cause other environmental problems, but the push for electric vehicles is creating an array of new environmental issues. When the batteries are damaged, or short-circuit in a recycling plant, they explode and start fires. Small lithium batteries, the ones found in cellphones and laptops, caused at least 26% more fires at waste and recycling facilities from 2016 to 2019. Electric car batteries pose an even greater danger because each one contains hundreds of small lithium cells. If one cell isn’t disposed of properly, the battery can explode.

The delicacy of the battery-dismantling process almost mandates a human touch, but manually disabling the batteries is hazardous. Special disposal sites must be built for old batteries so they don’t cause fires and pollution. Batteries can be recycled but only an estimated 5% worldwide are. It’s cheaper for manufacturers to make new batteries than to melt down old ones and retrieve the minerals (which releases greenhouse gases). Until the U.S. has special recycling plants that can separate useful minerals from waste, and automated processes to disable the batteries, used electric-vehicle batteries will pile up and present a huge danger.

Even when the batteries are still being used, they can cause fires. Last month GM recalled its all-electric Chevrolet Bolt for a second time after a series of battery fires. Meanwhile, owners are being told to charge their cars to only 90% capacity, park their cars outside immediately after charging them and not to charge them overnight.

Battery fires aside, electric vehicles are touted as carbon neutral, but that claim doesn’t consider that their batteries need more materials to build than do combustion engines. One lithium-ion car battery weighing 1,000 pounds requires extracting some 500,000 pounds of material from mines. A combustion engine, in contrast, weighs an average of 350 pounds and uses a mere 25,000 pounds of petroleum over its entire life. Producing and processing these materials expends energy, and the more energy expended, the more heat-trapping carbon dioxide is released.

Quantifying the carbon emissions from making batteries and some of the other emissions associated with electric vehicles is a tricky business. There are plenty of studies on the emissions from producing electricity to charge electrics or from the factories making their batteries. There are far fewer studies focusing on the mining that supplies a battery’s minerals. Generating electricity in remote mining areas, running the equipment, making the chemicals to refine the ore and transporting the material to electric-car factories all produce carbon, notes Mills, of the Manhattan Institute. Until all the energy that directly or indirectly goes into electric vehicles over their lifetime can be quantified, it will be impossible to determine whether they generate lower emissions than standard cars or more.

Carbon emissions aren’t the only environmental cost of making batteries. The batteries use not only lithium but also manganese, cobalt and nickel, and building and operating mines to produce these minerals comes with its own environmental debits. Take mining for lithium, for example. It’s such a water-intensive process that in Chile’s Salar de Atacama salt flats, it’s consumed 65% of the water, forcing the area’s residents to pump water from neighboring regions.

The proposed Thacker Pass mine in Nevada will use 3,224 gallons of water and 5,800 tons of sulfuric acid a day, resulting in 354 million cubic yards of mining waste, sulfuric acid discharge and “modestly radioactive uranium,” according to the mine’s environment impact statement. Additionally, the mine will harm or destroy the habitat of local wildlife and lower the water table by an anticipated 12 feet.

Salvation Isn’t Coming

These economic, logistical and environmental impediments, while sizable, may not be insurmountable. Necessity is the mother of invention, and companies all over the world have taken up the challenge. In California’s Salton Sea, CalEnergy Resources says that it can draw lithium directly from briny water, significantly lowering the environmental impact. In China, the electric-car-maker Nio has introduced a swappable battery service that cuts charging time and prices for vehicles.

But even if, in some hypothetical world, electrics could be totally carbon neutral and every American made the switch, global carbon emissions would drop by only 2.4%. In fact, if the entire American transportation industry, including airplanes, switched to electric, global emissions would go down only 5%.

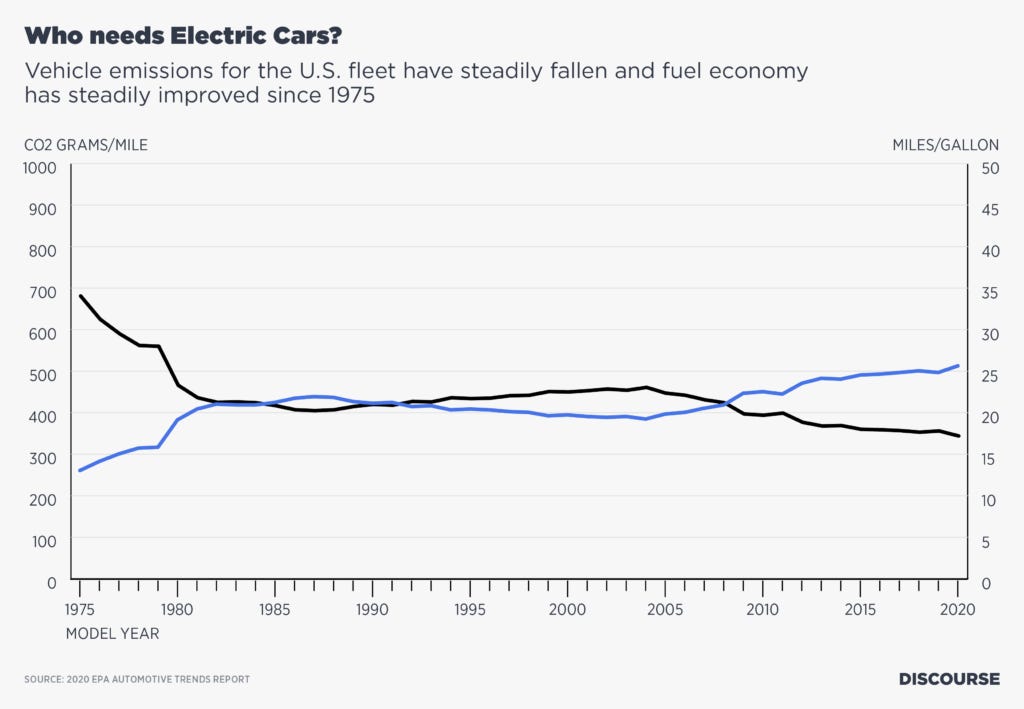

Electric vehicles, however, can’t be carbon-neutral—making them and driving them will always use an immense amount of materials and energy—and they won’t be delivering environmental salvation. It’s pure folly for governments on all levels to spend billions in a massive effort to build an industry that enjoys little demand. A better idea would be combustion-engine vehicles that are more fuel-efficient, which would result in a “real, measurable reduction in emissions,” says Mills. Standard engines beat back a challenge from battery-operated ones early in the last century, and they’re likely to do so again.